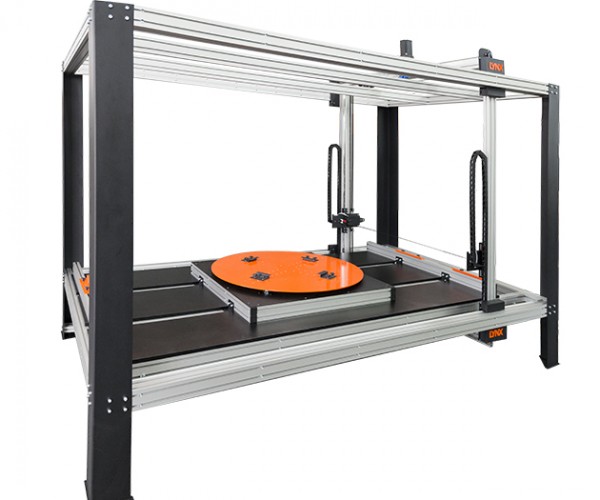

The 3D rotary table is an addition to the CNC cutting machine dedicated to carving 3D objects both symmetric (sphere, vase, bottle) and asymmetric (chess piece, car, sculpture). This fully automatic, computer-controlled device operated by a stepper motor suits all models of LYNX TERMCUT foam cutters. All you need to do is place it on the machine table, position the foam block, and start carving.

The CNC machine’s rotary table can be used together with shape or straight wire.

If you want to carve multiple symmetric-shaped elements, use shape wire. A shape wire is a thick wire (with a diameter of 1mm or greater); bend it to form the contour of the symmetric 3D object. Mount the wire on the holder. The cutting motion is straightforward. The shaped wire goes into the material, stops, and the table rotates 360 degrees. After rotation, the shaped wire is pulled out of the material.

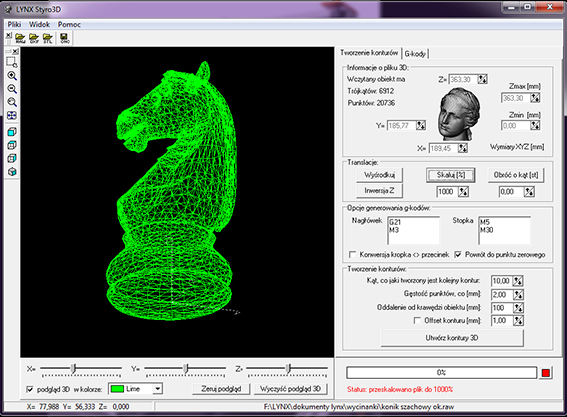

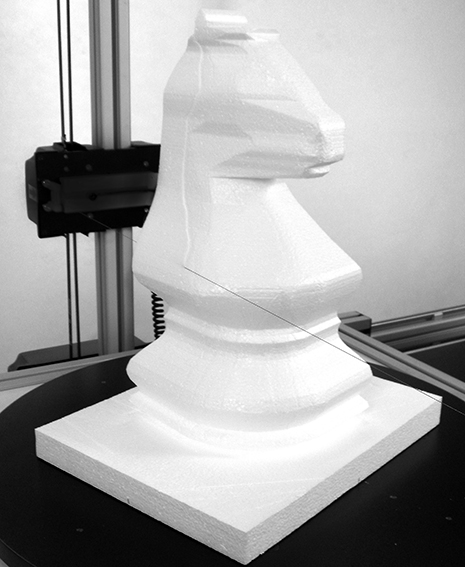

If you want to carve asymmetric 3D objects (car, chess piece), use the STYRO3D program provided with the LYNX TERMCUT foam cutter. It automatically generates data for individual cutting sections for asymmetric 3D objects. Prepare the object’s design in RAW, STL, or DXF format. Import the 3D file into STYRO3D, set cutting parameters and precision (number of cutting sections), and start carving.

For carving symmetric 3D objects, first, prepare the contour design. Do this in the LYNX TERMCUT software or import predesigned vector graphics. Set the number of cutting sections, ranging from 4 to 180, depending on whether you want a quadrilateral or completely circular shape. The cutting machine software automatically sets the rotation angle for each cut. Place the foam block on the table, set the starting point, send the settings to the machine (with a single click), and start carving.