The lathe dedicated to LYNX TERMCUT hot wire cutters is adapted to the machine’s height. It’s used for carving round, symmetrical objects like railings and columns. When combined with a milling tool, it’s used for shaping asymmetrical 3D objects.

The CNC cutter lathe is an automated computer-controlled device, operated by a stepper motor. It consists of two movable holders mounted on the machine table.

Carving using the lathe and CNC cutting machine can be done in 3 ways:

- lathe + straight wire.

- lathe + shape wire.

- lathe + milling tool.

Carve symmetric 3D objects using the CNC cutter lathe and straight wire:

- Prepare the object’s contour design in the LYNX TERMCUT cutter program or import predesigned vector graphics.

- Set the number of cutting sections; you can set from 4 to 180 sections to achieve a quadrilateral or circular shape.

- Place the foam block horizontally between the lathe holders and set the starting point.

- Send the file with the settings to the cutter (with a single click), press start, and wait for the machine to carve the designed shape.

In this case, you don’t need to prepare a design since the wire defines the object’s shape. Begin the cutting process by bending the shaped wire into the desired shape.

- Set the starting point.

- The shaped wire goes into the material.

- The lathe rotates the material by 360 degrees.

- The shaped wire is pulled out, creating a symmetric object.

The LYNX TERMCUT cutter in the Multitool version allows for the precise carving of detailed 3D objects. Using the lathe and milling tool, it’s possible to create asymmetric, very detailed objects.

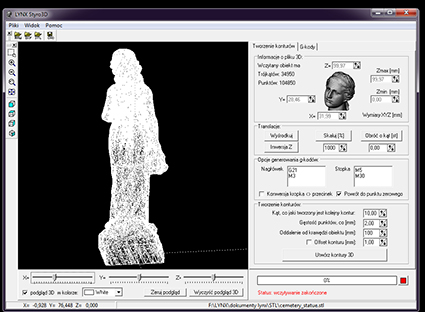

- Import the file with the object’s design into the TURN 3D app.

- Software converts the image into numeric data – it controls both the milling tool and lathe.

- Set parameters for the precision of carving.

- Place the material horizontally on the table, between the lathe holders.

- The milling tool moves along the material.

- When the milling stops, the lathe rotates according to the obtained data, and the milling tool starts moving in the opposite direction.

This type of carving process is time-consuming but also allows for carving highly complex forms, such as detailed human figures.