- 28 June 2023

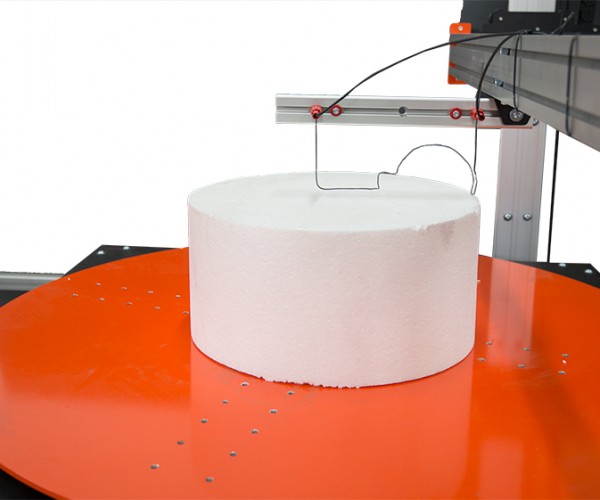

A shape wire is an additional carving tool available for all LYNX TERMCUT machine models. It is used together with the rotary table or lathe depending on what cutting effect we want to get.

A shape wire is mounted on the cutter’s axis (horizontally or vertically), replacing the standard wire. It’s a thick, hot wire with a thickness of 1mm or more. It can be bent into various shapes depending on the desired result. It cuts both concave and convex shapes. Shape wire for CNC hot wire foam cutters provides great results in the mass production of 3D objects.

The carving process with shaped wire can be conducted in two ways, both using the rotary table and the lathe.

The first type of carving is a straight cut with a 360-degree rotation.

- Bend the shape wire into the contour shape of the element.

- Mount it on the machine arm and place the material block on the rotary table (for vertical cutting) or on the lathe (for horizontal cutting).

- The carving motion is straightforward: the shape wire moves forward toward the material, goes into it, and stops.

- The material block is rotated on the table or lathe by 360 degrees.

- After a full rotation, the shaped wire is pulled out of the material.

- A symmetric 3D object is obtained, such as a vase.

The second type of carving with shape wire is spinning.

In this case, the wire defines the shape of the object. Begin the carving process by bending the shaped wire into the desired form.

- Set the starting point.

- The shaped wire enters the material.

- The lathe rotates the material by 360 degrees.

- The wire exits, creating a symmetric object.