- 28 June 2023

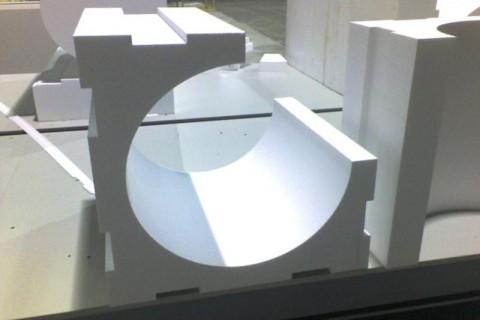

Precast concrete elements are a widely adopted solution in construction. The factory production of wells, bridges, columns, pools, etc., ensures precision and significant time savings. For manufacturing these elements, styrofoam molds are commonly used, cut with CNC cutting machines. These machines automatically produce a series of identical shapes, ready for casting.