- By LYNX Poland

- In Articles

XPS and EPS are both constructed from the same synthetic material – polystyrene, however they have slightly different properties and appearances. These differences stem from the way the polymer is processed. Which one is warmer, XPS or EPS foam? Which performs better in terms of thermal insulation? Let’s deep dive into the details!

XPS: Extruded Polystyrene

XPS is the result of polystyrene being foamed and extruded. This process yields a nearly smooth material, with a closely packed cell structure only visible at high magnification. Consequently, extruded polystyrene boasts excellent thermal properties and high mechanical strength. It is lightweight and does not absorb water, reducing the risk of mold and mildew formation within its structure.

XPS is both user and environmentally friendly. It is self-extinguishing and perfect for recycling. It is commonly used in construction for thermal insulation and in interior design for creating concealments and ornaments, such as decorative moldings and interior stucco. Due to its low water absorption, extruded polystyrene is suitable for spaces with higher humidity levels, such as kitchens, laundry rooms, basements, or bathrooms.

EPS: Expanded Polystyrene

Styrofoam (EPS foam) consists of expanded microgranules of polystyrene. During the expansion process, these granules expand and form styrofoam beads. Individual beads adhere to each other to create large styrofoam blocks, from which styrofoam boards are cut for various insulation purposes.

ESP foam can have varying densities, affecting its compressive strength. This is denoted by EPS ratings like EPS 40 or EPS 100. A higher EPS rating indicates better resistance to compression, greater hardness, density, and lower water absorption capacity. One of styrofoam’s advantages is its limited vapor permeability, making it suitable for application under various types of plaster without concerns about wall moisture. Like XPS, ESP foam is self-extinguishing, as it does not fully combust and does not fuel fires. Instead, it disintegrates and carbonizes under high temperatures and open flames.

Key Differences Between XPS and EPS foam.

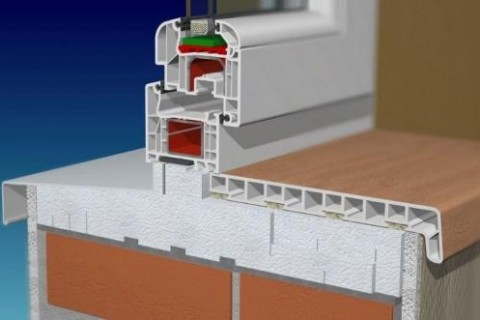

The differences as a result of the processing of polystyrene affect not only their appearance and texture but also their properties. In comparison to XPS, EPS foam has higher water absorption, a more porous and non-uniform structure, greater thermal expansion, and lower hardness. Consequently, extruded polystyrene outperforms styrofoam in terms of thermal and water resistance. XPS is also thinner than EPS, allowing for thinner insulation layers. This is particularly significant in insulating smaller, single-family houses, as it facilitates slimmer walls and reduces the thickness of window and door recesses. Moreover, XPS aids in eliminating thermal bridges in hard-to-reach areas due to its smooth texture, making it easier to produce thinner yet mechanically resilient boards.

It’s worth noting that XPS is a more expensive material. However, when budgeting, consider that the superior insulation properties of the material will lead to energy savings in the long run.

Applications of EPS and XPS foam

Extruded and expnaded polystyrene find application at different stages of construction and renovation projects. XPS is the preferred choice for insulating foundations, especially in areas with high groundwater levels. It retains its structural integrity even through freeze-thaw cycles and provides a durable foundation wall for years to come. Styrodur is also ideal for insulating roofs and crafting decorative finishing elements.

EPS, on the other hand, is typically used for insulating building facades. It offers adequate thermal insulation properties and is easy to install. EPS is also suitable for insulating foundations in low-traffic areas and on sandy or gravelly soils, as well as insulating walls and ground-level floors.

Choosing Between EPS and XPS foam

EPS is a compact material with resistance to water vapor diffusion and frost. It can be used for insulating foundation walls, roofs, or mitigating thermal bridges. Due to its thinness, it is favored in modern construction when achieving slim partitions is desired. Its thermal conductivity (λ) ranges from 0.029 to 0.034 W/mK, meeting the most stringent construction standards while maintaining the aesthetics of the building.

Styrofoam, with its looser structure, allows more air permeation than XPS. Its thermal conductivity (λ) falls between 0.030 and 0.042 W/mK, providing effective thermal insulation. It is more cost-effective but has lower resistance to mechanical damage and water absorption.

When choosing between EPS and XPS foam, consider the composition of the walls or the elements of the building you need to insult. The location of the building, traffic intensity, geological conditions, and exposure to atmospheric factors should also influence your decision.

EPS and XPS foam are, both derived from polystyrene, offer unique advantages and applications in the realm of insulation and construction. While making decision consider specific project requirements, budget constraints, and environmental considerations. Whether you opt for the compact, resilient XPS or the cost-effective, porous styrofoam, these materials contribute significantly to enhancing the energy efficiency and longevity of your building.

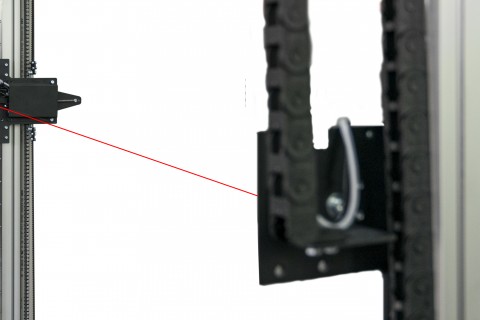

Do you work with XPS and EPS foam? Are you looking for reliable and user-firendly CNC technology which make your everyday work easier? Check out our CNC hot wire cutters. We are tha manufacter of hot wire foam cutters that work excellent for both industry and small scale production of polystyrene elements of different shapes.