CNC machines are remarkable devices that transform binary and pulse signals into precise mechanical movements. Their primary purpose is the production of three-dimensional components. such devices offer high repeatability, production speed, and precision that conventional machines cannot match.

How Do CNC Machines Work?

The acronym CNC stands for Computerized Numerical Control, indicating computer-controlled numerical devices. Compared to other types of machinery, these devices are distinguished by their unparalleled precision. They feature an integrated mini-computer that automatically plans and executes tasks with minimal operator intervention. The role of a human operator boils down to programming the CNC machine and creating or selecting vector graphics.

The operation of CNC machines is based on a computer-managed control system that automates, monitors, and controls the machine’s movements. Precise and repeatable work is achievable through a closed-loop system. Each part of the machine returns to its original position after completing the intended task, with its position continuously corrected according to the controller’s programmed parameters.

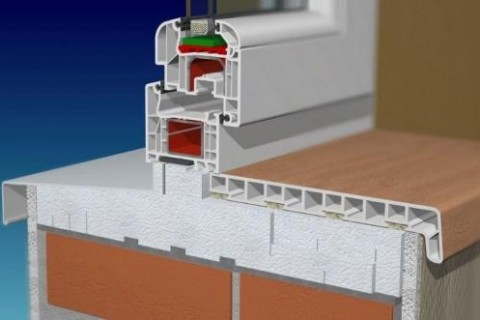

Basic CNC machines operate in two axes, while more advanced ones can have up to five axes, performing both linear and rotational movements, automatically rotating workpieces. This allows for almost hands-free cutting and shaping.

Popular Types of CNC Machines

In the market, you can find various types of CNC machines, including milling machines, lathes, drills, waterjet cutters, lasers, and the latest technological solutions like CNC hot wire cutters. These highly efficient and incredibly precise machines excel in cutting and shaping components while providing full control over operating parameters.

CNC Control Systems

CNC machines employ three control systems: point-to-point, linear, and contour. The point-to-point control guides the machine through straight-line movements, parallel to the coordinate axes. Linear control positions the machine at a specified point relative to the workpiece. Contour control is multi-axis and facilitates various material shaping tasks, such as 3D designs.

Key Advantages of CNC Machines

CNC machines perform tasks quickly and effortlessly, providing precise components with accuracy up to 100%. Cutting multiple components of the same shape does not require modifying the plotter’s settings; simply load a new material and restart the machine. This ensures that the prepared products match the design perfectly and require no further finishing.

Their speed saves time, completing tasks faster than manually operated machines, increasing production efficiency. Devices enable process automation by executing tasks automatically, reducing operator involvement to a minimum. This ensures consistency and repaetable work, guaranteeing same components and the ability to set processing cycles in advance.

Safety is also a crucial aspect of CNC machines operation. Automated CNC work eliminates manual handling and minimizes potentially dangerous situations and accidents, ensuring a safe production environment.

CNC machines are versatile and can process materials of unconventional shapes in multiple planes, lowering production costs. Precision in work helps optimize material usage, generate less waste, and reduce production costs. CNC machines minimize human errors while decreasing labor costs. Traditional material processing requires an operator to handle each machine, while CNC machine operators can handle several stations.

Choosing the Right CNC Machine for Cutting

Selecting the appropriate CNC cutting machine accelerates project execution and reduces processing costs. What should you consider when choosing a CNC machine for cutting? Review the chosen model, CNC system, machining accuracy, and main feature specifications. Ensure that the machine’s price includes full software licenses and check which graphic file formats the plotter can import. Essential details impacting future use include:

- Machine type

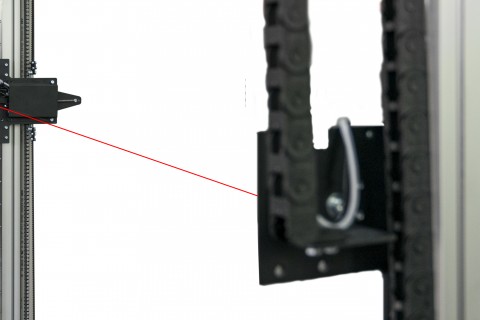

- Wire breakage detection that halts the cutter

- Temperature control adjustments through software

- The number of wires (cutting tools) and wire tension, whether adjusted automatically or manually, also affect ease of use and work quality.

CNC Machines and Your Business

The selection of a CNC machine should align with your business’s profile, the type of materials you cut, their quantity, thickness, and properties. The scale of your company and the size of your operator team are also essential considerations. When determining the budget for CNC machine investment, remember that, in most cases, a cutter pays for itself quickly by optimizing production time and processes.

In applications requiring machining processes like drilling, engraving, milling, cutting, shaping, and producing 2D or 3D components, CNC plotters excel. Our product range includes devices equipped with modern software and essential accessories. We assist in selecting the right CNC cutting machine based on individual needs and provide operator training for efficient operation.